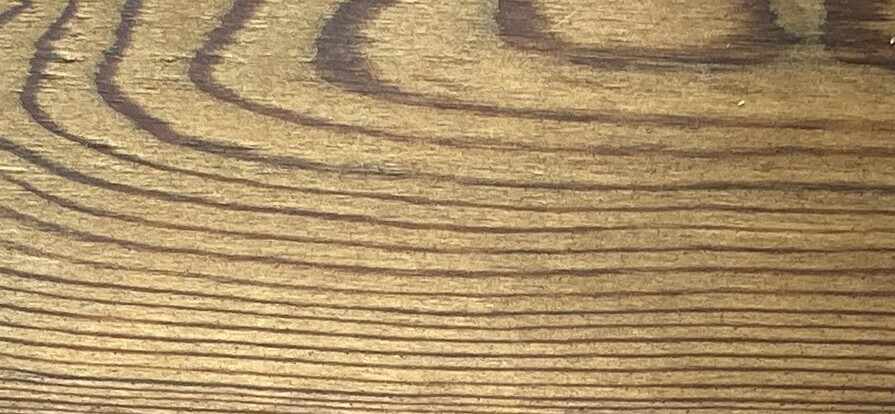

Thermo-treated ash has preserved the warmth, essence, and soul of ancient wood. The benefits of thermo-treated ash wood are its durability (class 1), beauty, dimensional stability, environmental friendliness, and quality. Only by heat treatment are we able to produce produce wood which does not rot or grow mold, does not vary in size and is also environmentally friendly. Heat treatment is the computer-controlled process of wood heating which is carried out in a special chamber at a temperature of 190 to 212 ° C. During this process all the moisture, acids and bacteria in the wood are eliminated. Ash is a good alternative to tropical wood.

Heat treatment ensures a very long service life and dimensional stability. Most importantly – the whole process is chemical-free.

The most notable property of larch is its stunning resistance to rotting. For centuries, mankind has witnessed the unique performance of structures built from Siberian larch. This experience has led us to refer to it as the “Wood of Eternity”. We use larch in our bench collection, as larch will retain its qualities without any chemical processing or finishing for decades. It is one of the most durable types of wood in terms of weather conditions, primarily due to its unique gum content.

Tropical wood is often the preferred outdoor wood material for its quality, durability, and stability. In addition to its strength and quality, tropical hardwood has a unique appearance. Untreated tropical wood has a fresh delicate pink shade which turns silver-grey over time. Note that the fading of the wood tone is not considered as a quality defect.

Because we care for the nature, we have chosen only FSC marked tropical hard wood for our production.

We are using high-quality, dense Nordic pine that is impregnated with a preservative agent and then boiled in linseed oil under vacuum. Linax- treated pine is an environmentally friendly wood option, that is very suitable for extreme climate conditions and has a very good track record for repelling moisture.

The oil is boiled into the surface of all six sides, which reduces moisture absorption into the wood and gives a dimensionally stable outcome with protection against rot and longer maintenance intervals.

Heartwood and sapwood absorb varying amounts of pigment, which can give rise to colour variations on the surface, but this will fade when the material is exposed to UV rays from the sun and rain.

Galvanizing is an anti-corrosion treatment in which the products are covered with a thin layer of zinc. Without any damage the surface will last for many years keeping the details from rusting. When exposed to the atmosphere, zinc reacts with oxygen to form zinc oxide which further reacts with water molecules in the air to form zinc hydroxide. Finally zinc hydroxide reacts with carbon dioxide in the atmosphere to yield a thin, impermeable, tenacious and quite insoluble dull gray layer of zinc carbonate which adheres extremely well to the underlying zinc, protecting it from further corrosion.

Stainless steel also known as inox steel differs from carbon steel by the amount of chromium present. Carbon steel rusts when exposed to air and moisture. Iron oxide film (the rust) is active and accelerates corrosion by forming more iron oxide. Stainless steel contains sufficient chromium to form a passive film of chromium oxide, which prevents further surface corrosion and blocks the corrosion from spreading into the metal’s internal structure.

Cor-ten is a high-strength structural steel with exceptional weather resistance. Cor-ten steel is almost pure carbon steel that is only slightly alloyed to create a patina protective layer on its surface to withstand the weather. The patina layer is initially reddish-brown (a shade similar to rust), becoming darker over time. In industrial and more aggressive environments, patina forms on steel faster and darkens more than in clean rural environments. However, a protective patina layer cannot form if the steel surface is constantly wet or dirty. Rainfall is often enough to keep surfaces clean.

To keep powder coated items looking new and attractive and to reduce the overall maintenance costs, an additional protection can be applied on the products surface. The application of the anti-graffiti lacquer is done the same way as the regular powder painting. Anti-graffiti lacquer is based on polyurethane chemistry which releases a blocking agent during the curing process. This solution is designed to allow the simple and rapid removal of most forms of graffiti and is recommended for use where resistance to graffiti is required. Typical end uses include train, tram and bus components, bus shelters, telephone boxes, school furniture and play equipment, outdoor park and street furniture, garden furniture, road signs, fencing and public buildings.

As a side effect, the lacquer will add gloss so the final finishing of the product, which will not be matt even for matt powder coating option.

Cleaning instruction of products covered with anti- graffiti lacquer:

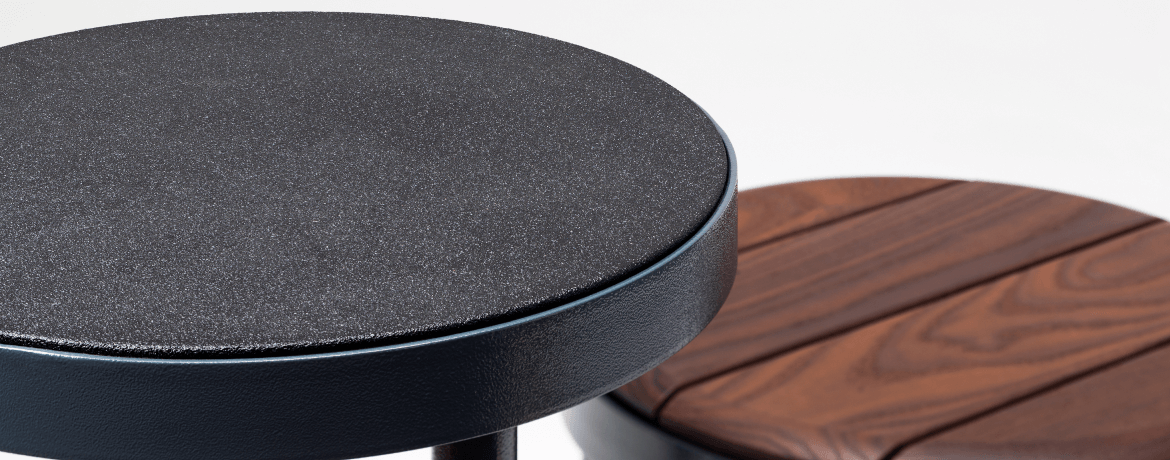

EXTERY has brought to the urban furniture field the material which has been mostly used for industrial application. Two-component, high performance non-aromatic polyurea/polyurethane hybrid spray elastomer system is commonly applied to protect surfaces of intensely used areas like boat decks and van floors.This substance has excellent thermal stability and good chemical resistance, providing extra protection for the metal. It also creates an interesting surface structure that matches designer products perfectly.Metal benches are exceptionally practical for urban spaces, but during the cold season their appeal diminishes. Elastomer surface layer makes metal warmer to sit on while protecting the products against corrosion and graffiti. Elastomer-covered bike racks are more resistant to mechanical damages and also avoid scratching bike’s frame.